Missing Stock Location and Configuring Inventory

1.6 min read

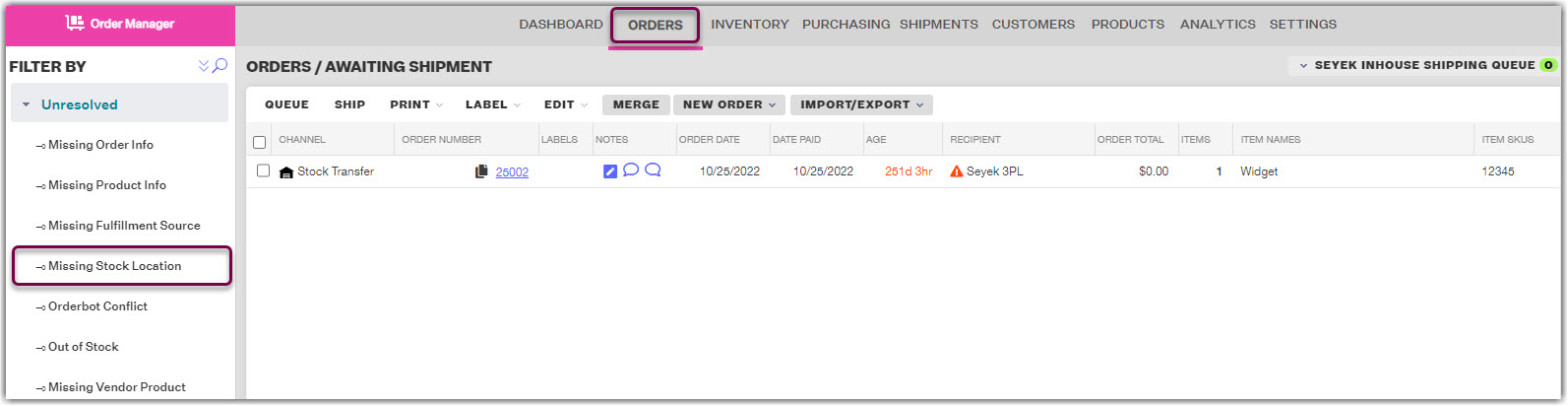

|When orders are in the Missing Stock Location status, this means that the stock for the order does not have a pick location, or simply it is sitting in an 'Unconfigured Stock' status.

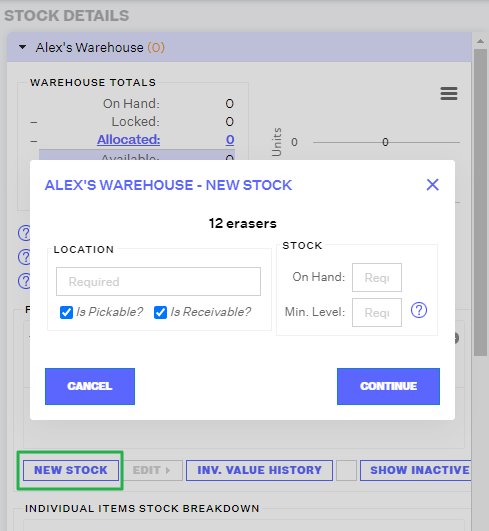

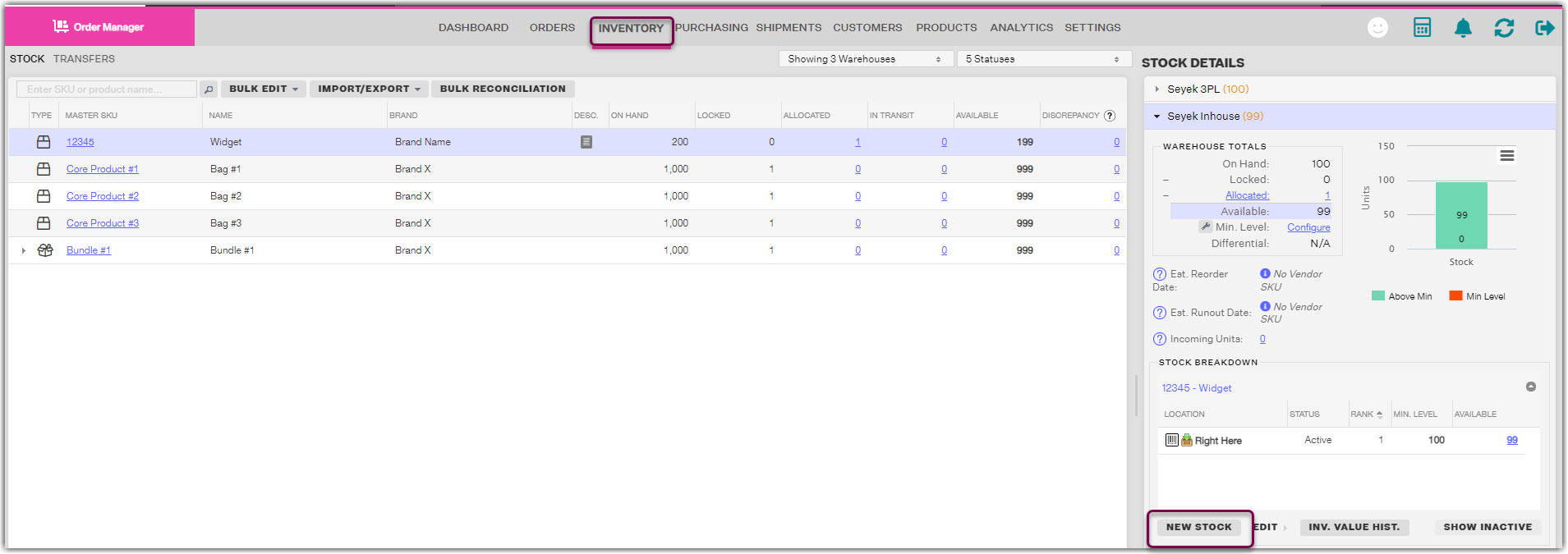

To configure stock for an in-house warehouse:

Navigate to the Inventory module and search for your affected product. Select your product and click on New Stock and you will see a pop-up window where you can enter in the pick location of this product, check/uncheck whether or not this product is pickable or receivable, and configure the quantity of on-hand stock and the minimum stock level for this product.

- Location can get as granular or as simple as you would like it to be. For example, aisle 1, shelf 13, bin 56 can be A1S13B56. This is for internal purposes.

- Is Pickable? is asking if this product can be picked from this location. If you uncheck this box, this product cannot be picked from the in-house warehouse, and therefore the order cannot be fulfilled.

- Is Receivable? is for receiving inventory from your purchase orders once they arrive at the warehouse. If you uncheck this box, this product cannot be received to this location when ordering. In order to receive stock replenishment for this product, this must be checked.

- Stock: On Hand will update how many units are currently at that particular location

- Min. Level allows you to set a minimum level alert for specific locations at a warehouse. This is independent from the Warehouse Min. Level

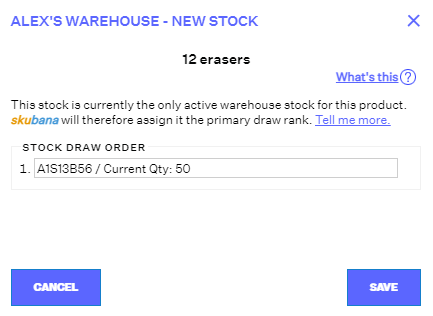

Once this is done, and you click Continue, you will see:

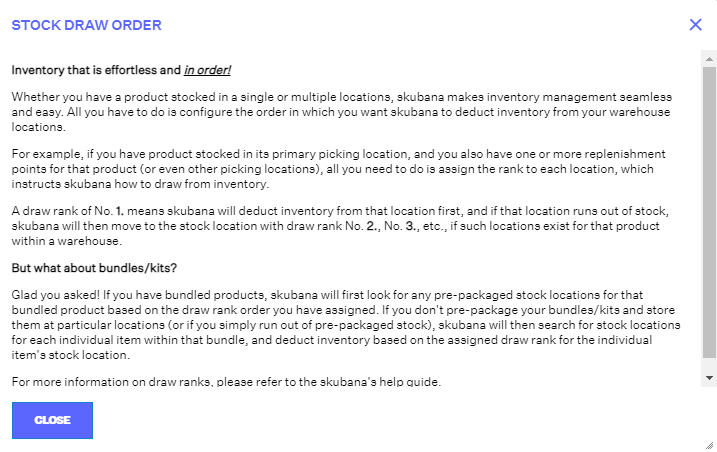

Notice here that this is talking about the draw order, or being assigned as the primary draw rank.

Draw Rank refers to the location order from which this product will be picked; "Pick this item from location x, and once it runs out, pick from location y"

If everything seems to be in order, click Save, and your stock will have been configured for the selected warehouse.

*For every location that this product is in, it is important to configure the stock for all of these locations. Can be done manually through the UI or in bulk through spreadsheets.

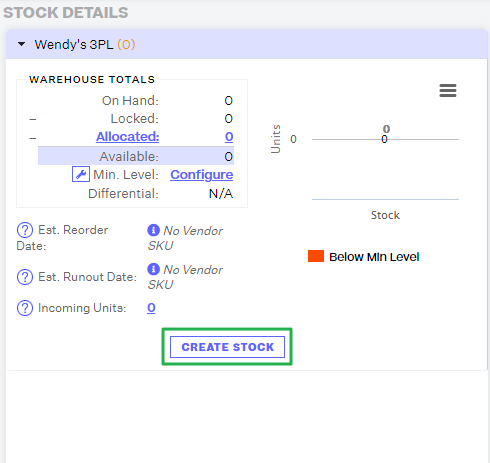

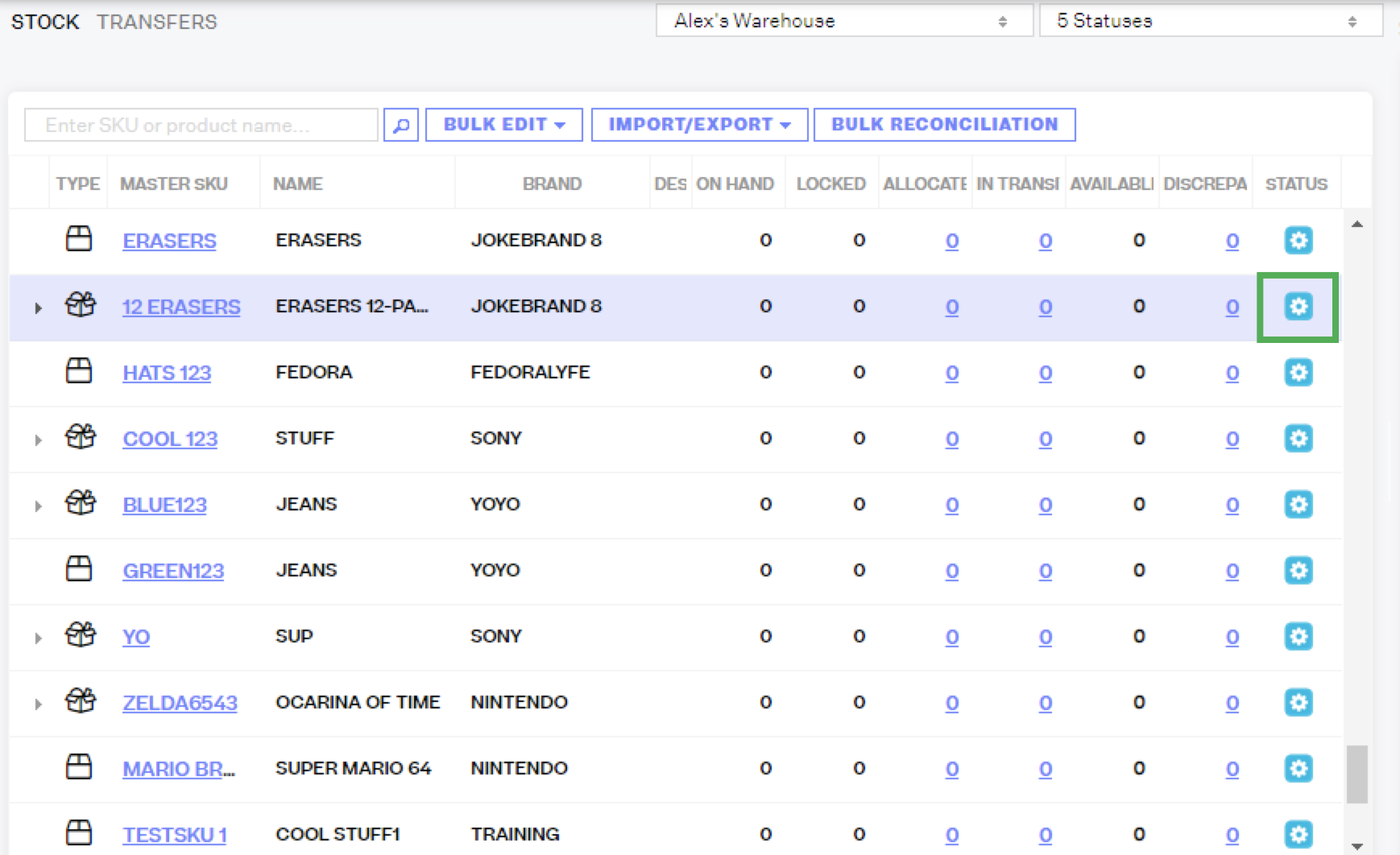

To configure stock for a 3PL or Dropship Vendor:

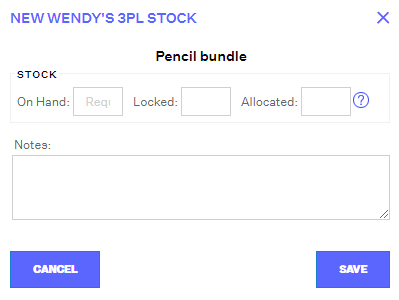

For 3PL, dropship, or retail, simply click on the product that must be configured in the Inventory module, and on the right side, click on the 3PL, dropship, or retail drop-down menu. Once you do this, click the Create Stock button and you will see a pop-up with a more basic version of entering stock information.

*The only required field is 'On Hand'. Locked refers to inventory that is being saved for a specific reason. Allocated refers to inventory that must be put aside due to orders. It is important for the user to communicate with the 3PL, dropship, or retailer to see how this should be configured.

Once this is set, click Save.